Reach us at: info@visiondiecasting.com

Reach us at: info@visiondiecasting.com

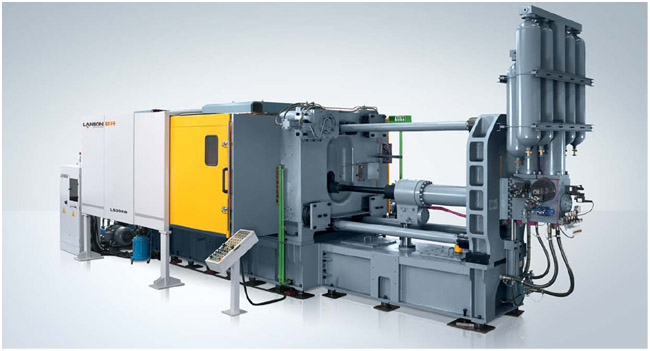

Through domestic and international mainstream design technology, and fully research and insight into the customer’s habits and needs, LANSON research and develop the newest high-quality die-casting equipment with stable casting quality and accurate technology by its international technical talents.

LS Series cold chamber die casting machine has greatly improved the equipment stability, efficiency and practicability, contains a highly integrated, highly automated, efficient integrated application of technology die-casting unit, better to help all customer showing their advantages in today’s competitive environment.

LANSON’s R&D technical team has the richest experience of large tonnage cold chamber die casting machine equipment manufacturing, research and development.

STABLE AND RELIABLE HIGH PERFORMANCE INJECTION SYSTEM

POWFUL AND HIGH EFFICIENCY CLAMPING SYSTEM

1. High Rigidity

2. High Precision

3. High Strength

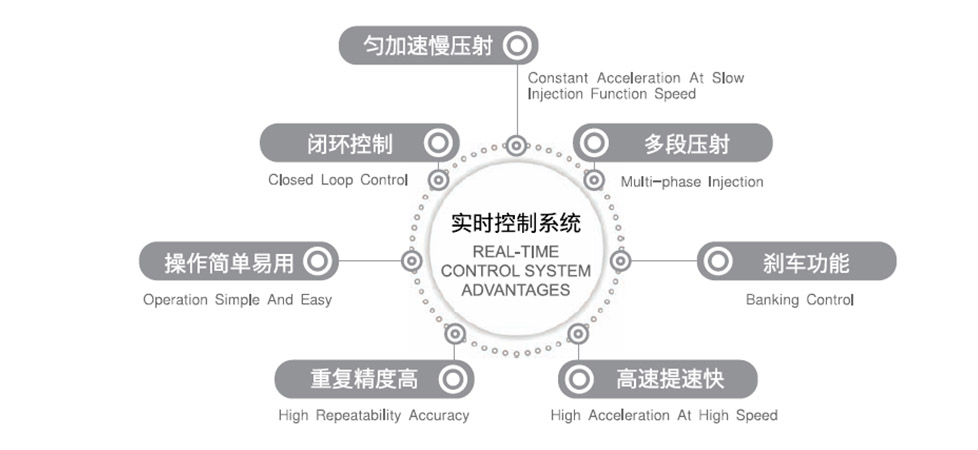

PERFECT FUNCTIONAL DIE CASTING CONTROL SYSTEM

EMBEDDED REAL TIME CONTROL INJECTION SYSTEM

LANSON is one of the domestic manufactures which apply the real time control technology on the die casting machine. The developed by embedded real time control injection system combines excellent hydraulic design system and accurate control system. Can be effectively execute the injection speed according to the user required instruction, and change the speed at the appointed injection position. The perfect match of real speed and setting speed fully realize the accurate control of injection process, and provide perfect multi-phase injection speed control and pressure control curve. Coupled with the constant acceleration at low speed, brake function at the end of the mold filling, etc., providing the user a strong die casting control, suitable for complex structure of high quality die casting parts.