Reach us at: info@visiondiecasting.com

Reach us at: info@visiondiecasting.com

Hot chamber die casting can be used with zinc, magnesium, and other low melting alloys. The hot chamber machine contains the melting pot, while the cold chamber melting pot is separate and the molten metal has to be ladled into the shot sleeve. With the internal mechanism, it makes the hot chamber the faster of the two processes. Other advantages of the hot chamber process include reduced porosity and longer die life from utilizing alloys that do not erode or dissolve the machine when put under heat or high pressure.

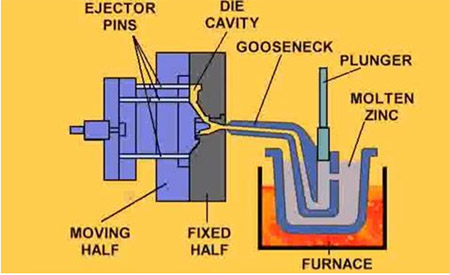

Hot chamber machinery contains the alloy melting pot as part of the machine itself and uses a gooseneck to inject material from the pot into the die. Internals of the machine pair the plunger and port to control how much molten metal is injected into the die.

When the port seals, the metal rests in the cavity to cool and solidify. Next, the plunger retracts and the casting itself can be removed once the die opens. This design allows hot chamber die casting to be a continuous process.

Because the melting pot is internal, hot chamber machinery is used for materials with lower melting points. The alloys are also limited to materials that won’t erode or dissolve the metal of the machine when put under heat or high pressure. Typical materials used in hot chamber die casting are zinc, lead and magnesium alloys.